CMM program prepares students for careers in machining

“I enjoy teaching this program so much, that after I retired in 2014 from this program, I spent the next five years wishing I had not,” says Danny Pancake. Pancake is the program coordinator for the Computerized Manufacturing and Machining program at Ashland Community and Technical College.

“I love working with the machines and the materials and producing parts for projects and for various other ACTC programs, but I really enjoy the interaction with students. I love to watch them learn and grow, and I love helping them secure employment at the end of the tenure with us,” he added.

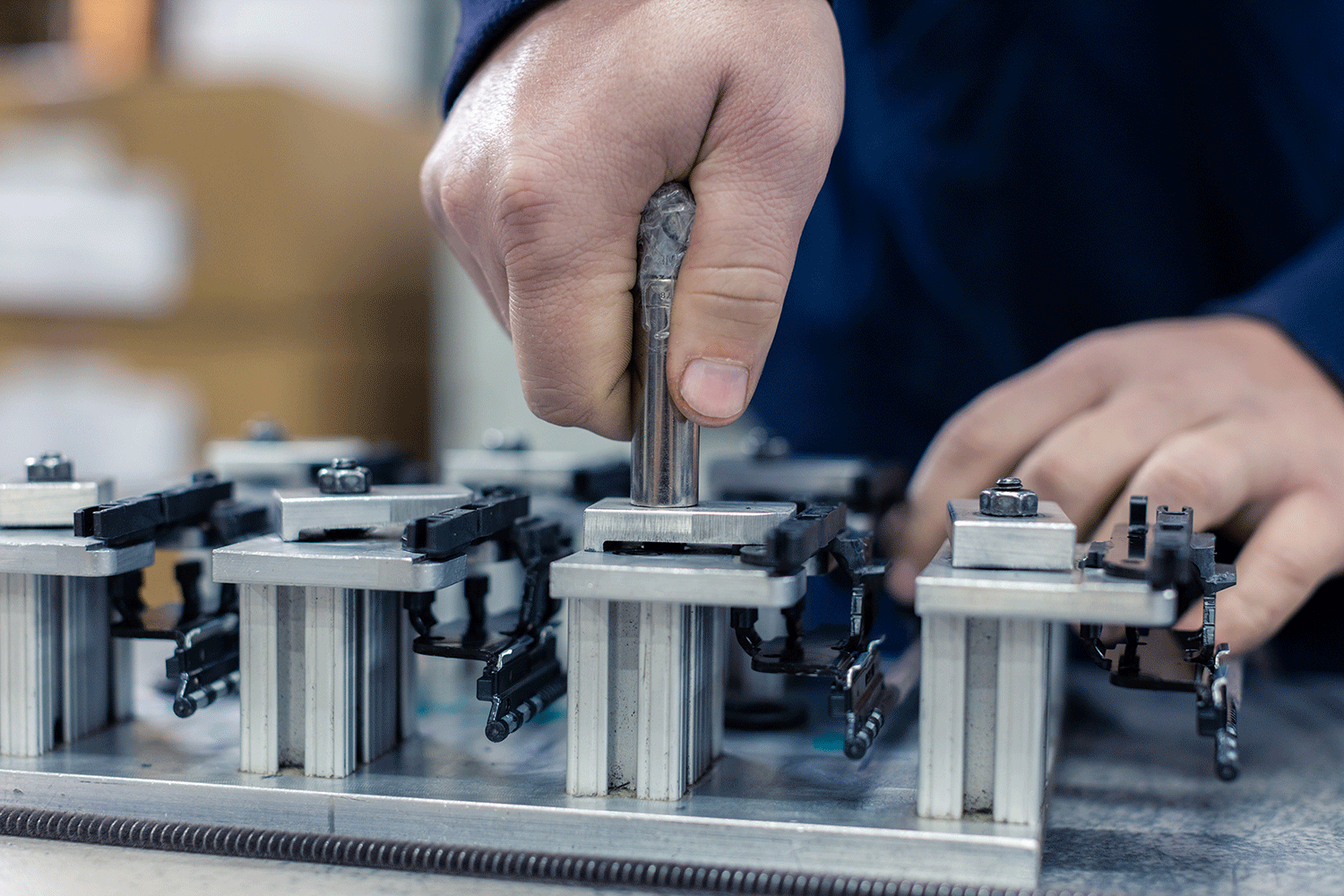

Through classroom instruction, students in the CMM program receive a hands-on experience learning to position work pieces, adjust machines and verify the accuracy of machine functions and finished products.

ACTC offers two diplomas and three certificates to prepare graduates for machine shop employment. Certificate and diploma credits may be applied toward an Associate in Applied Science Degree in General Occupational/Technical Studies.

Mason Tomaselli, who is in his last semester of the program, says affordable tuition, small class size and the ease of getting help or feedback from instructors were all reasons he chose ACTC, specifically CMM.

“What I learn directly applies to on-the-job skills I need,” he says. “I chose the CMM program because I like being able to envision a part or tool that's useful in everyday life and then be able to manifest that idea. I'd also taken some blueprinting classes in high school, so it was a program I had some familiarity with. I opted for CMM instead of drafting because I wanted to take my drawing a step farther by being able to take a part off paper into reality.”

Classes in the program include: Basic, Intermediate and Advanced Machining, among several others.

“Students entering the CMM program are from every area of life. I have taught both men and women, young and middle aged, and I find the one ingredient they all need to succeed is determination,” said Pancake.

Work activities in machine shops involve applying knowledge of machine capabilities, the properties of material and shop practices to set up and operate various machines.

“The most enjoyable parts of the program are working with your hands and computers, learning about different machines and getting to try new things I might not have gotten to if I wasn't in the program,” Tomaselli says. “One of the most satisfying feelings is starting with an idea and piece of metal, and being able to turn those into a useful finished project.”

A machine tool specialist (machinist) shapes metal to precise dimensions. The technically skilled machinist must be able to read blueprints and transform this information into a part, product or entire machine. The machine tool specialist is skillful in the use of tool room and production equipment, including lathes, grinders, milling machines, saws and drilling machines.

“A person should enroll in CMM because it is an excellent field where new technology is always being discovered and implemented. We make things and we make them well,” says Pancake. “We are trained to develop skills that are in high demand and we make parts that are very much needed. We make everything from bolts or shafts to gears and pulleys. We make parts for trucks, trains, aircraft, refrigerators, washing machines, bicycles and motorcycles. We make parts for engines, windmills, turbines and any other precise metal object that is used in any fashion.”

Based on research conducted by the Kentucky Center for Statistics (KYStats) in 2019 for the TENCO region, salary can range from $27,642 to $50,811 based on experience.

“Machinists don’t make the world go round, but we do make the world work. A student entering this program can be assured that if they apply themselves, they will find suitable and desirable employment that pays well,” said Pancake.

“As of this semester, I have already found a job with Steen Cannons, where I use what I learned in class every day. If you show up to class and make it known that you're willing to work hard, companies will seek you out. People are always calling Mr. Pancake looking for a machinist,” Tomaselli says.

The degree and diploma credential programs are four semesters in length. Certificates can be earned in as little as one semester or as many as three, based on pace and the certificate chosen.

“The opportunities for employment in this highly skilled technological field are many and the variety of types of work are also plenteous. If these students do decide to further their education, they would be well suited for entry into various engineering programs, at any of our local universities,” said Pancake.

Danny Pancake can be reached at danny.pancake@kctcs.edu.

Learn more about the CMM program by visiting https://ashland.kctcs.edu/education-training/program-finder/computerized-manufacturing-machining.aspx